PLPG-350 Full-auto Panel Air Filter Paper Pleating Production Line

Consists

1. Paper de-coiler

2. Heater

3. Water steam device

4. Pleating machine

5. Hot-melt unit

6. Belt conveyer

7. Automatic counting

Specification

| Width | 90~320mm |

| Pleating height |

20~58mm |

| Speed | 5~25m/min (adjustable) |

| Temperature range |

0~300℃ |

| Heater power |

8.5kw |

| Transmission power of pleater | 0.75kw |

| Conveyer belt transmission power | 0.25kw |

| Conveyer belt speed | 0~5m/min.(adjustable) |

| Working air pressure | 0.6Mpa |

| Power supply | 380V/50Hz |

| M/C weight | 1100kg |

| M/C size | 7500×950×1750mm(L×W×H) |

Features

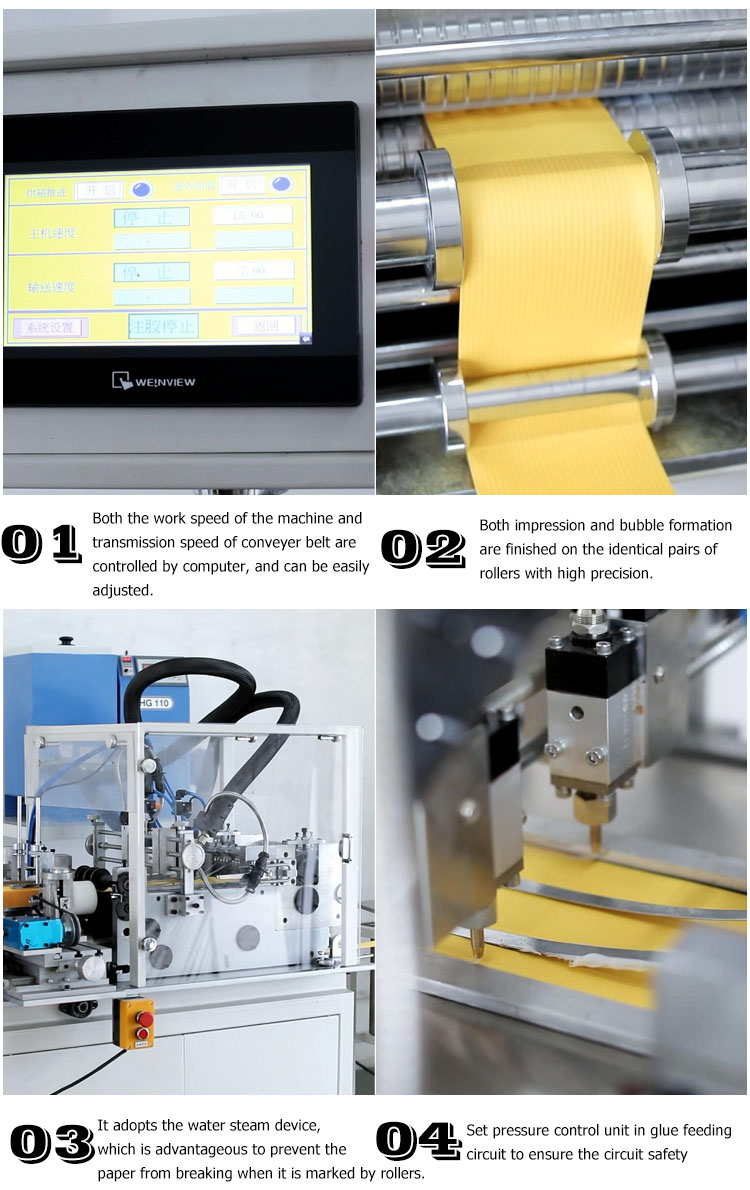

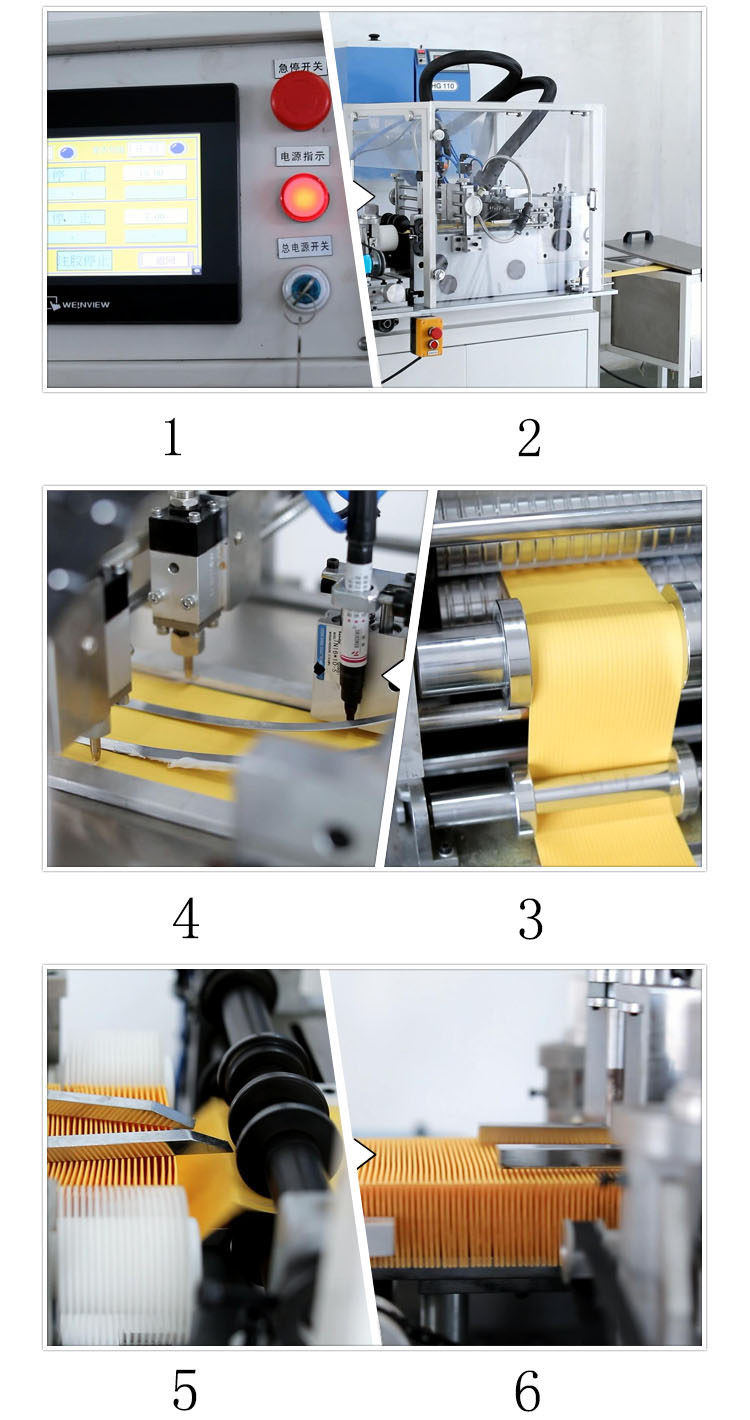

1. Both the work speed of the machine and transmission speed of conveyer belt are controlled by computer, and can be easily adjusted.

2. Both impression and bubble formation are finished on the identical pairs of rollers with high precision.

3. The temperature can be predetermined in accordance with the requirement of the technological process. When the pleating machine runs and the heater will start to work automatically.

4. It adopts the water steam device, which is advantageous to prevent the paper from breaking when it is marked by rollers.

5. Melt quickly, the glue dispensing quantity can be easily controlled by frequency converter.

6. Set pressure control unit in glue feeding circuit to ensure the circuit safety.

7. Both the rubber hose and nozzle are independently temperature controlled, and easy to operate.

Applications

It is technically used fo manufacturing the car panel filter.

Our leiman filter solution group is controlling shareholder for Pulan filter machine factory, we are invest for one stop filter service together. We are the exclusive export company for Pulan filter machine factory. We only provide exclusive lifetime (7*24h) service to customers who purchase from our company.

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.