Jan . 30, 2025 02:23 Back to list

polyester air filter material

Polyester air filter material has emerged as a revolutionary solution in the realm of air filtration systems, offering a blend of efficiency, durability, and cost-effectiveness that places it at the forefront of environmental sustainability. As industries continue to evolve towards more eco-conscious practices, understanding the intricate workings of polyester air filter materials becomes invaluable.

In addressing authoritativeness, the implementation of polyester in air filtration systems is backed by extensive research and industry application. Numerous studies have demonstrated its superiority over traditional materials such as fiberglass and cellulose. Polyester’s ability to trap and hold dust particles without releasing them back into the environment enhances indoor air quality, directly impacting health and productivity levels—factors that are becoming increasingly pivotal in workplace design and building certifications like LEED and WELL. Trustworthiness of polyester air filter materials is further cemented by their ease of maintenance and longevity. Polyester filters are often washable and reusable, a feature that significantly reduces replacement frequency and waste generation. This reusability aligns with global initiatives aimed at reducing carbon footprints and promoting sustainable resource management, making polyester filters not only a pragmatic choice but also an environmentally responsible one. Moreover, polyester filters’ compatibility with various environmental standards and regulations ensures that industries can seamlessly integrate these filters into their systems, avoiding compliance issues. Their thermal and chemical stability also means they're less likely to degrade or emit harmful substances over time, safeguarding both industrial processes and the surrounding ecosystem. To encapsulate, polyester air filter material is not merely an option but a pivotal component in modern air filtration systems. Its blend of efficiency, longevity, and environmental friendliness makes it an unparalleled choice across various industries seeking to optimize their operations and reduce ecological impacts. Adopting polyester filters is a step towards embracing a future where air quality is maintained with precision, aligning with global standards for health, efficiency, and sustainability.

In addressing authoritativeness, the implementation of polyester in air filtration systems is backed by extensive research and industry application. Numerous studies have demonstrated its superiority over traditional materials such as fiberglass and cellulose. Polyester’s ability to trap and hold dust particles without releasing them back into the environment enhances indoor air quality, directly impacting health and productivity levels—factors that are becoming increasingly pivotal in workplace design and building certifications like LEED and WELL. Trustworthiness of polyester air filter materials is further cemented by their ease of maintenance and longevity. Polyester filters are often washable and reusable, a feature that significantly reduces replacement frequency and waste generation. This reusability aligns with global initiatives aimed at reducing carbon footprints and promoting sustainable resource management, making polyester filters not only a pragmatic choice but also an environmentally responsible one. Moreover, polyester filters’ compatibility with various environmental standards and regulations ensures that industries can seamlessly integrate these filters into their systems, avoiding compliance issues. Their thermal and chemical stability also means they're less likely to degrade or emit harmful substances over time, safeguarding both industrial processes and the surrounding ecosystem. To encapsulate, polyester air filter material is not merely an option but a pivotal component in modern air filtration systems. Its blend of efficiency, longevity, and environmental friendliness makes it an unparalleled choice across various industries seeking to optimize their operations and reduce ecological impacts. Adopting polyester filters is a step towards embracing a future where air quality is maintained with precision, aligning with global standards for health, efficiency, and sustainability.

Latest news

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

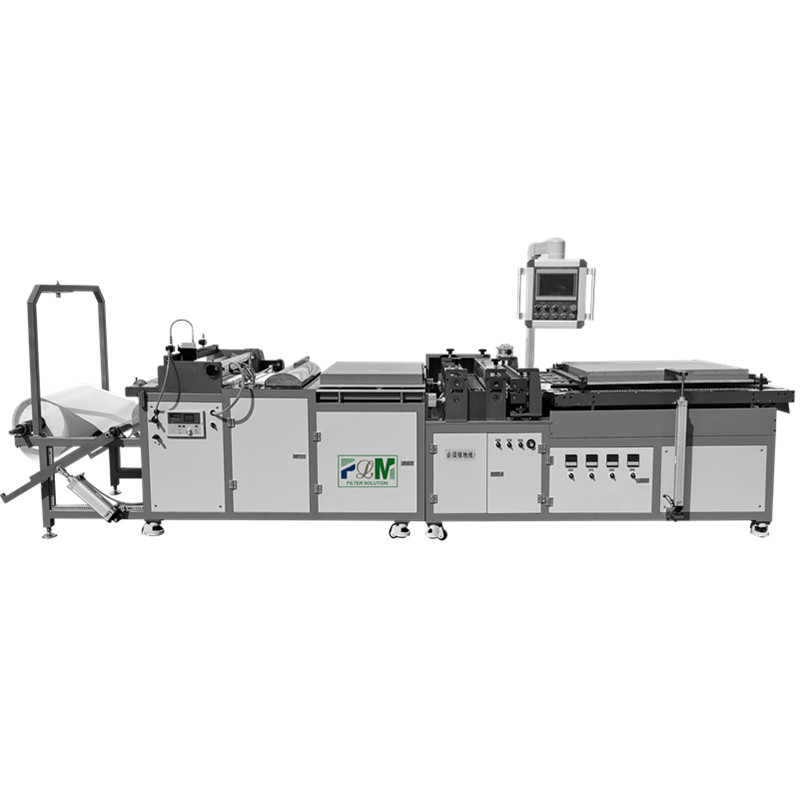

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025