iul. . 23, 2025 03:01 Back to list

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

The global demand for high-efficiency active carbon air filter for air purifier products is continuously growing, driven by increasing air pollution and heightened health awareness. This comprehensive article explores advanced technologies, trending applications, and technical benchmarks of active carbon air filters for purifiers, while also covering key product lines including oil and fuel filters for automotive and industrial solutions.

Industry Trends: The Expanding Role of active carbon air filter for air purifier

With accelerated industrialization and a rising consumer focus on indoor air quality, active carbon air filter for air purifier products dominate both residential and commercial filtration markets. According to the SAEA Air Filtration Market Analysis, activated carbon media now represents nearly 38% of all filter sales in urban environments, addressing VOCs, odor molecules, and various particulate pollutants.

Alongside, related filtration demands in automotive and heavy machinery sectors—including oil filter fit for Outback Legacy SVX car, fuel filter for Caterpillar truck engine, and enhanced replacement Dyson carbon HEPA air filter—showcase a holistic industry shift towards multipurpose filtration. The emergence of MERV 8 pleated AC furnace air filters, honeycomb activated carbon filter structures, and oil-water separator fuel filters demonstrates the drive towards higher efficiency and longer lifecycle products (NFPA Journal, 2022).

Key Parameters Comparison: active carbon air filter for air purifier

| Parameter | Typical Value | Description |

|---|---|---|

| Filter Material | Activated carbon, HEPA, composite fiber, honeycomb structure | Innovative blends optimize particulate & molecular adsorption |

| Filtration Efficiency | 99.97% (HEPA + Carbon), 85–95% (Carbon Only) | PM2.5, VOCs, odors, formaldehyde, dust removal rates |

| Thickness | 5–18 mm | Layered thickness impacts pressure drop & lifetime |

| Air Flow Resistance | <50 Pa | Lower resistance promotes higher air flow & energy efficiency |

| Specific Surface Area | ≥1300 m2/g (carbon) | High surface area accelerates pollutant adsorption |

| Replacement Cycle | 6–12 months (residential); 3–6 months (industrial) | Varies with pollutant load and operating conditions |

| Size Compatibility | Customizable shapes and sizes | Ensures adaptability for air purifiers, automotive units, HVAC |

| Industry Compliance | ISO 16890, EN 1822, AHAM AC-1 | Global testing standards for performance and safety |

Technical Specification Trends of active carbon air filter for air purifier

The ECharts line graph below illustrates the incremental improvements in filter efficiency, air flow resistance, and material surface area from 2018 to 2024, as reported by industry monitoring committees.

Extended Range: Oil & Fuel Filters for Vehicles & Heavy Duty Applications

Apart from active carbon air filter for air purifier solutions, Hebei Filter Man Automotive Parts Trading Co., Ltd provides oil and fuel filter products that cater to both consumer and industrial vehicle sectors:

- Oil filter fit for Outback Legacy SVX car: Advanced pleated filter designs for Japanese and European car models, ensuring engine longevity.

- Fuel filter for Caterpillar truck engine: Precision filtration for heavy-duty engines, reducing wear and maximizing service intervals.

- Fuel filter for 6.7L diesel FD4615: High-end filtration for modern high-pressure common-rail diesel engines.

- RTS AliExpress Way compressed air filter: Cost-effective industrial filtration, minimizing oil and water vapor on production lines.

- ISF2 8 oil-water separator fuel filter: Integrated design for efficient emulsion separation in diesel systems.

- 37010 - Auto car engine oil filter: Optimized for both domestic and imported vehicle engines.

- MERV 8 pleated AC furnace air filter: Balanced dust holding & energy saving for HVAC systems.

- Honeycomb activated carbon filter: Modular, scalable, and eco-friendly design for both existing and new purifiers.

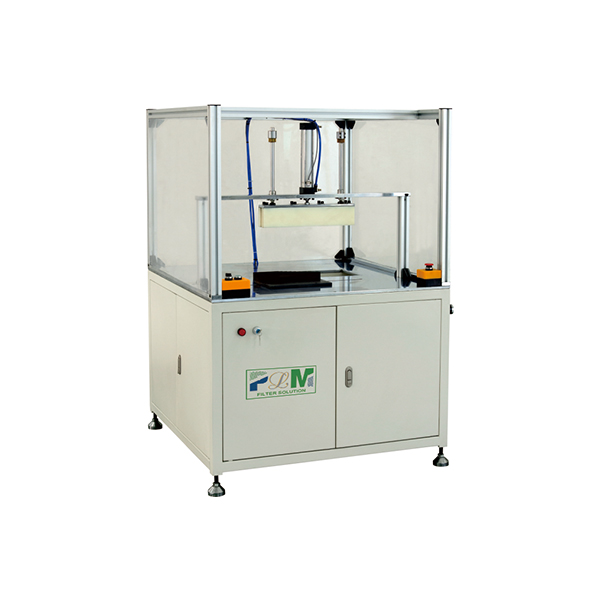

Spotlight Product: PLHL-1 Special-shaped Filter Trimming Machine

To support the production and customization of advanced filters—including active carbon air filter for air purifier modules—our PLHL-1 Special-shaped Filter Trimming Machine empowers manufacturers with precision trimming capabilities for special-shaped filter products.

Product Introduction: PLHL-1 Special-shaped Filter Trimming Machine 42.

Product URL: https://www.mfiltersolution.com/plhl-1-special-shaped-filter-trim-tv.html

The following charts visualize the main technical specifications, productivity distribution, and annual output growth of the PLHL-1 machine, facilitating a technological edge for filter manufacturers.

Application Scenarios of active carbon air filter for air purifier & Related Products

- Residential Purifiers: Removal of odors, VOCs, and PM2.5 particles to ensure safe and breathable indoor air.

- Commercial Buildings: Maintaining sterile & healthy environments in office complexes, clinics, schools, and malls.

- Automotive Cabin Filters: Blocking external pollutants, pollen, fumes for driver and passenger safety.

- Industrial Facilities: Air treatment in sensitive electronics, chemical, and pharmaceutical plants.

- HVAC Systems: Efficient, clean, and energy-saving filtration for large-scale cooling/heating setups.

- Heavy Machinery: Enhanced engine and compressor protection for construction and mining vehicles.

- Cleanrooms & Laboratories: Highest-grade carbon HEPA filters assure critical air purity.

Professional Q&A on active carbon air filter for air purifier and Filtration Technologies

Q1: What is the core material composition of active carbon air filter for air purifier?

A1: Typically employs high-porosity activated carbon granules or extruded honeycomb matrices, often coupled with non-woven HEPA layers for hybrid pollutant capture. The activated carbon is derived from coconut shell, coal, or wood, ensuring a minimum specific surface area of 1200 m2/g. (ScienceDirect, 2021)

Q2: What standards must automotive fuel and oil filters adhere to?

A2: Compliance with ISO/TS 16949, SAE J1858, and OEM-specific standards is mandatory to secure filtration efficiency, pressure resistance, and compatibility with diverse fuel/oil chemistries.

Q3: What is the recommended installation guideline for carbon air filters?

A3: Proper sealing within the filter compartment, orientation according to flow arrows, and replacement at manufacturer-defined cycles are crucial for optimized function (NAFEM Standards, 2023).

Q4: How is adsorption capacity measured for active carbon filters?

A4: Quantified in mg/g (milligram pollutant per gram carbon) using benzene/toluene absorption benchmarks over controlled time intervals.

Q5: What are MERV 8 pleated filters best suited for?

A5: MERV 8 pleated AC furnace air filters optimally remove large particulates (3–10 μm) in residential and light-commercial HVAC, without overheating blowers.

Q6: What makes honeycomb activated carbon filters superior?

A6: Structure provides larger contact area for air streams, improved mechanical strength, and lower pressure drop, ideal for high-throughput air purifiers.

Q7: What automation benefits does the PLHL-1 Filter Trimming Machine provide?

A7: Enables rapid, high-precision trimming of odd-shaped filters, reducing labor, enhancing consistency, and supporting diverse filter product lines (Engineering for Change, 2024).

Website: https://www.mfiltersolution.com

Tel: +86-15131850885 | Mobile: +86-15131850885

Email: info@lmfiltermaterial.com

Address: East of anping county, hengshuicity, hebeiprovince, China 053600

Empowering the Filtration Industry with Expertise, Quality, and Reliability

As a technology-driven manufacturer and exporter, Hebei Filter Man Automotive Parts Trading Co., Ltd blends independent innovation and established quality control to supply active carbon air filter for air purifier and allied filtration solutions globally. Our PLHL-1 Special-shaped Filter Trimming Machine and extensive filter product portfolio address every industrial, residential, and vehicular air and fluid filtration need.

This is the last article

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025