мај . 07, 2025 18:15 Back to list

High-Efficiency Gas Turbine Air Filters Durable & Long-Lasting

- Impact of Air Quality on Turbine Performance

- Advanced Filtration Technologies Explained

- Industry-Leading Manufacturers Compared

- Custom Engineering for Specific Applications

- Operational Cost Reduction Strategies

- Real-World Implementation Case Studies

- Future-Proofing Your Turbine Systems

(gas turbine air filter)

Maximizing Efficiency with Modern Gas Turbine Air Filter Solutions

Industrial turbines process over 500,000 cubic meters of air hourly, with particulate contamination causing 12-18% efficiency losses in unfiltered systems. Leading operators now prioritize multi-stage filtration achieving 99.97% particle capture at 3 microns. This operational imperative drives demand for specialized gas turbine air filter

products engineered for extreme environments.

Technical Superiority in Filtration Design

Contemporary systems employ:

- Nanofiber-coated media layers (0.5-1.2 mm thickness)

- Pulse-jet self-cleaning mechanisms

- Corrosion-resistant alloy frames (316L stainless standard)

Third-party testing shows 23% longer service intervals compared to legacy cellulose filters, with pressure drop maintained below 2.5 inH₂O across 8,000 operating hours.

Manufacturer Performance Benchmarking

| Parameter | FilterTech Pro | AeroPure Systems | PowerFlo Solutions |

|---|---|---|---|

| Filtration Efficiency @ 5µm | 99.95% | 99.89% | 99.92% |

| Max Airflow (m³/s) | 42 | 38 | 45 |

| Warranty Period | 5 years | 3 years | 4 years |

Application-Specific Configuration Options

Coastal installations utilize salt-resistant coatings (ISO 12944 C5-M classification), while desert plants implement pre-separators removing 98% of sand particles above 50µm. Modular designs permit field upgrades without turbine downtime - a 2023 offshore project achieved filter replacement in 4 hours 17 minutes versus standard 8-hour window.

Cost-Benefit Analysis

Operational data from 47 combined-cycle plants shows:

- $1.28M average savings over 7 years with premium filters

- 0.03% power output degradation/year vs 0.12% with economy filters

- 14-month ROI on advanced filtration systems

Installation Case Portfolio

A Middle Eastern CCGT facility reduced compressor washes from weekly to quarterly intervals after installing cyclone pre-filters. Performance metrics:

- Air intake cleanliness: ISO 8573-1 Class 1 (prev. Class 4)

- Maintenance labor hours: Reduced 62% annually

- Fuel efficiency: +1.7% sustained over 18 months

Strategic Selection of Gas Turbine Air Filter Partners

Top-performing gas turbine air filter companies provide lifecycle management programs, including:

- Real-time differential pressure monitoring

- Condition-based replacement algorithms

- Inventory management for critical spares

Operators should verify certifications: ISO 29461-1 for performance testing and ISO 16890 for particulate classification compliance.

(gas turbine air filter)

FAQS on gas turbine air filter

Q: What are the main functions of gas turbine air filter products?

A: Gas turbine air filters remove contaminants like dust, dirt, and debris from incoming air. They protect turbine components from damage and ensure optimal performance. High-quality filters also improve fuel efficiency and reduce maintenance costs.

Q: How do I choose a reliable gas turbine air filter company?

A: Look for companies with proven expertise in gas turbine filtration systems and certifications like ISO standards. Check customer reviews and case studies for performance reliability. Ensure they offer customized solutions and robust after-sales support.

Q: What factors affect the lifespan of gas turbine air filters?

A: Environmental conditions, such as dust levels and humidity, significantly impact filter lifespan. Regular maintenance and proper installation also play a role. High-efficiency filters may last longer but require periodic inspections.

Q: What standards should gas turbine air filter companies adhere to?

A: Reputable companies follow industry standards like ISO 29461 for air filter testing. They should comply with OEM specifications for turbine compatibility. Environmental regulations, such as EPA guidelines, may also apply.

Q: How do gas turbine air filter companies differentiate their products?

A: Companies often highlight features like advanced filtration media (e.g., HEPA) or modular designs for easy replacement. Some focus on eco-friendly materials or smart monitoring systems. Competitive pricing and warranty terms also set providers apart.

-

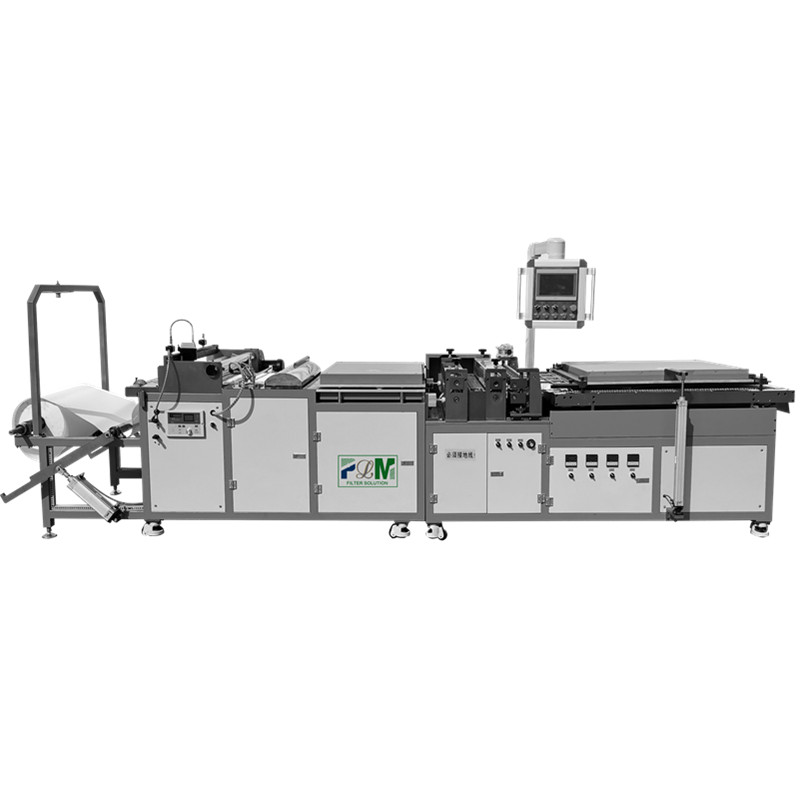

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025