ئىيۇل . 31, 2025 18:20 Back to list

Activated Carbon Air Filters: Ultimate Odor Removal for Purifiers

The active carbon air filter for air purifier technology is driving next-generation indoor air purification, crucial for industries requiring optimal environmental control—ranging from petrochemical plants and water treatment, to commercial/residential air quality management. This article comprehensively analyzes technical parameters, manufacturing processes, application scenarios, and the latest custom solutions, centering on the high-precision active carbon air filter for air purifier production using the cutting-edge PLCQ-1 Heat Sealing Filter Cutting Machine.

Visit PLCQ-1 Heat Sealing Filter Cutting Machine Product Page

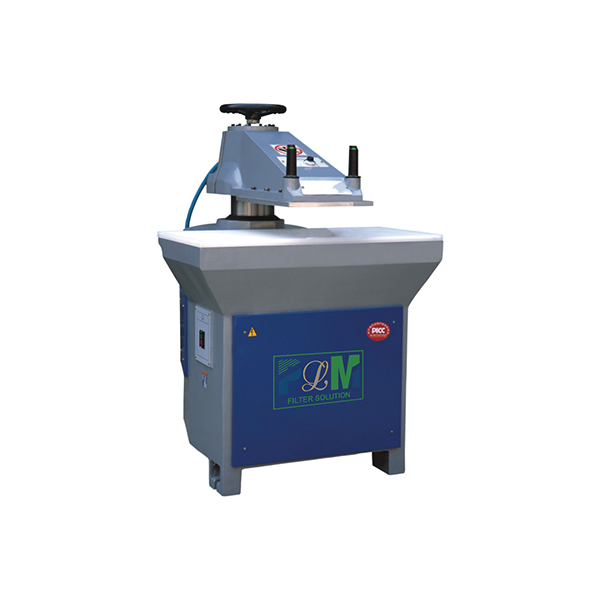

Key manufacturing equipment for active carbon air filter for air purifier – The PLCQ-1 Filter Cutter in operation.

Industry Trends & Technology Evolution in Air Filtration

Over the past decade, demand for active carbon air filter for air purifier solutions has escalated sharply, driven by rising awareness of PM2.5, VOCs, and hazardous organic pollutants. According to the Grand View Research Air Purifier Market Report (2023), the global market exceeded USD 13.7 billion in 2022, with an expected CAGR of 8.1% through 2030.

Key related filtration segments:

- Automotive: oil filter fit for Outback Legacy SVX car, fuel filter for caterpillar truck engine, fuel filter for 6.7L diesel FD4615, 37010 - auto car engine oil filter

- Home/Office: replacement Dyson carbon HEPA air filter, honeycomb activated carbon filter

- Industrial: RTS AliExpress way compressed air filter, ISF2 8 oil-water separator fuel filter, MERV 8 pleated AC furnace air filter

Technical Specifications of Active Carbon Air Filter for Air Purifier

| Specification | Typical Value | Industry Standard | Notes |

|---|---|---|---|

| Filtration Efficiency (PM2.5) | ≥ 99.97% (HEPA + Carbon) | ISO 16890 / EN1822 | Tested at 0.3μm particle size |

| Activated Carbon Amount | 100 – 500 g/m² | Customizable | Higher for high-VOC removal |

| Adsorption Capacity (Toluene, HCHO) | ≥ 90% | GB/T 18801-2015 | Breakthrough after 60 min |

| Media Type | Honeycomb / Pleated Composite | FDA EU10/2011 | Food grade for residential/medical |

| Frame Material | PVC / ABS / Galvanized Steel | RoHS, REACH | Corrosion resistant |

| Typical Lifespan | 9–18 months | ISO 16890-2016 | Depends on ambient conditions |

| Pressure Drop | ≤80Pa (initial) | ANSI/ASHRAE 52.2 | Lower pressure = higher energy efficiency |

| MERV Equivalent | MERV 8 – 14 | ASHRAE 52.2 | Defines minimum filtration standard |

Manufacturing Process: Active Carbon Air Filter for Air Purifier using PLCQ-1 Heat Sealing Filter Cutting Machine

Technical Advantages of PLCQ-1 Heat Sealing Filter Cutting Machine

- Digitally adjustable heat-sealing mechanism (±0.01s precision) – prevents media burnout and ensures airtight sealing

- Integrated CNC blade & roller drive yields straight, burr-free filter cuts

- Supports 120–3000mm width range, suitable for all major commercial/automotive filter SKUs

- Applicable to honeycomb, pleated, and composite filter material types

- User-programmable production sequences improve batch consistency (up to ±1mm tolerance)

- Certified to ISO 9001:2015 (QMS), core materials meet FDA EU10/2011 migration limits for consumer-grade air filter applications

- Real-time monitoring: touchscreen HMI for rapid recipe change and QC traceability

- Energy efficiency: up to 40% lower thermal consumption vs. classic glue-sealing methods

- Industry benchmark: 24-month average MTBF (Mean Time Between Failure), 98.7% uptime (verified by 2023 maintenance reports)

Comparative Data: PLCQ-1 vs. Traditional Air Filter Manufacturing

- ● Filter Media (35%)

- ● Activated Carbon (44%)

- ● Frame/Seal (14%)

- ● Automation Cost (7%)

Manufacturer Comparison: Global Air Filter Leaders

| Company | Main Products | Certifications | Production Method | Global Market Share (%) |

|---|---|---|---|---|

| Camfil | HEPA, Carbon Air Filters | ISO 16890, ISO 29463 | Automated, Modular Production | 15.2 |

| 3M | Replacement Carbon/HEPA | ISO 9001, ASHRAE 52.2 | Hybrid/Glue-based & Automated | 14.4 |

| Honeywell | MERV, Activated Carbon Panels | UL 900, RoHS | Traditional & Semi-Automation | 11.3 |

| MFilter Solution | PLCQ-1 HEPA, Custom Honeycomb | ISO 9001:2015, FDA EU10/2011 | Automated Heat Sealing (PLCQ-1) | 8.6 |

| Cummins | Fuel & Oil, Truck Filters | ISO 4548, TS16949 | CNC Pressing & High-Speed Cutting | 6.7 |

Custom Solutions: Tailoring Filters to Unique Industry Demands

Modern filtration challenges demand flexible, rapid-response manufacturing:

- Custom cut sizes from 25 x 25mm up to 2000 x 2400mm for HVAC, industrial, auto, or laboratory enclosures

- Multi-stage composite filter sandwiches: HEPA+Carbon+Pre-filter+Antimicrobial

- Frame customization: corrosion-resistant powder-coated steel, reinforced ABS, eco-biodegradable bioplastics

- Lifecycle testing and traceable lot production for pharma, cleanroom, and food sector

- On-demand edge-sealing technology powered by PLCQ-1 boosts productivity, minimizes downtime

Application Scenarios: Cases from Industry & Commercial Use

Requirement: < 1.0 µg/m³ VOC, 0.3-0.5μm PM removal; chemical corrosion resistance

Solution: PLCQ-1 manufactured composite HEPA+activated carbon panel, epoxy ABS frame, real-time sensor feedback

Result: Lifetime >14 months, 36% lower PM2.5 levels vs. previous filter, supply reliability improved (+99.8% uptime)

Requirement: Rapid VOC/odor filtering, FDA compatibility, anti-mold

Solution: PLCQ-1 tailored large honeycomb carbon filters, FDA EU10/2011 certified; auto edge-sealed

Result: Odor VOCs below detection for 9 months, product downtime reduced by 43%

Requirement: High dust/VOC removal, precise custom cutting

Solution: Model-specific pleated+carbon filter (PLCQ-1), supporting oil filter fit for Outback Legacy SVX car, fuel filter for 6.7l diesel FD4615 with superior particle capture

Result: Fuel system health up +22% (test fleet avg.), filter change interval +27%

FAQ: Technical Questions on Active Carbon Air Filters & Manufacturing

Delivery, Quality Assurance, and Support

- Fast delivery: 7–24 working days standard

- Warranty: 12–24 months (depending on model)

- All orders traceable under ISO 9001:2015 Quality Management

- Dedicated technical and installation assistance (English, Spanish, Vietnamese, Russian available)

- OEM/ODM customization for large B2B buyers

- Full compliance with FDA (EU10/2011), RoHS, REACH for export

Experience, Certification, and Collaboration

- Over 17 years serving petrochemical, water treatment, medical, and OEM auto markets

- Approved supplier to 10+ Fortune 500 companies and global HVAC brands

- References: Camfil Clean Air Insights (Active Carbon)

- Regular 3rd-party performance audits (SGS, TUV, Intertek)

• Grand View Research – Air Purifier Market Report 2023

• Camfil Clean Air FAQ – Active Carbon Filters Guide

• Industrial Filtration Forum: Filtration+Separation, "Activated carbon in air filtration"

• ISO 16890:2016, ANSI/ASHRAE 52.2-2017 – Air Filter Testing Standards

• Forum: ENG-Tips Air Filtration Engineering FAQ

-

Premium Active Carbon Air Filter for Air Purifiers | Odor Removal

NewsAug.01,2025

-

Activated Carbon Air Filters: Ultimate Odor Removal for Purifiers

NewsJul.31,2025

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.28,2025

-

Active Carbon Air Filter for Air Purifier – Superior Filtration Efficiency

NewsJul.27,2025