Th8 . 18, 2025 01:00 Back to list

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

Advancing Air Purification: The Critical Role of Activated Carbon Filtration

In an era defined by growing environmental consciousness and stringent health standards, the demand for superior air quality solutions has never been more pronounced. Industries and households alike are increasingly seeking advanced filtration technologies to combat a spectrum of airborne contaminants, ranging from microscopic particulate matter to volatile organic compounds (VOCs) and noxious odors. This global imperative is driving innovation within the air filtration sector, particularly in the development and application of highly effective adsorbent media. Central to this evolution is the active carbon air filter for air purifier, a critical component engineered to address complex air purification challenges by leveraging the unparalleled adsorption capabilities of activated carbon. Its integration into various purification systems, including those found in residential, commercial, and even specialized industrial environments, underscores its indispensable value in safeguarding human health and sensitive equipment.

The market trend unequivocally points towards a greater emphasis on comprehensive air treatment, moving beyond mere particulate removal to encompass chemical and gaseous pollutant mitigation. This shift is influenced by escalating concerns over indoor air quality (IAQ) and the long-term health effects associated with exposure to VOCs originating from building materials, cleaning products, and industrial processes. For B2B decision-makers and technical personnel in sectors such as HVAC, automotive manufacturing, and chemical processing, understanding the nuanced advantages of activated carbon filtration is paramount. Our Environmental Car Air Filter Non-woven, for instance, exemplifies how advanced filtration media are being developed to meet diverse needs, offering solutions that enhance air quality, protect systems, and ensure compliance with environmental regulations. From large-scale industrial exhaust systems requiring robust solutions comparable to a `fuel filter for caterpillar truck engine` for air, to specialized applications demanding precision akin to `isf2 8 oil-water separator fuel filter` principles for gas separation, the principles of advanced adsorption remain vital.

The increasing complexity of airborne pollutants necessitates a multi-faceted approach to air purification. While traditional particulate filters, such as a `merv 8 pleated ac furnace air filter`, effectively capture dust, pollen, and other solid particles, they often fall short in addressing gaseous contaminants. This is where activated carbon technology excels, offering a porous structure specifically designed to chemically bond with and trap gaseous molecules. The specialized expertise in materials science and manufacturing processes required to produce high-performance carbon filters ensures that products like the active carbon air filter for air purifier not only meet but exceed industry standards. This foundational understanding is crucial for optimizing system performance, extending filter lifespan, and achieving desired air quality outcomes across a multitude of applications, including specialized vehicle filtration needs reminiscent of a `oil filter fit for outback legacy svx car` for cabin air, or the robust requirements for heavy machinery comparable to a `fuel filter for 6.7l diesel fd4615` in terms of durability and efficiency.

Technical Deep Dive: Manufacturing and Performance Specifications

The manufacturing process of an active carbon air filter for air purifier is a meticulously engineered sequence designed to maximize adsorption capacity and structural integrity. It typically begins with the selection of high-quality raw materials, primarily activated carbon sourced from coconut shells, wood, or coal, chosen for their inherent microporous structure and high surface area. This carbon undergoes a controlled activation process, often involving steam or chemical treatment, to further enhance its porosity and create a vast network of pores capable of adsorbing gaseous molecules. Following activation, the carbon can be processed into various forms—granular, pelletized, or finely powdered and impregnated into a non-woven fibrous media. The choice of form depends on the filter's intended application, balancing pressure drop, contact time, and adsorption efficiency. For instance, a `honeycomb activated carbon filter` design maximizes surface area while maintaining airflow.

The fabrication of the filter media involves binding the activated carbon to a substrate, typically a non-woven synthetic fabric, using specialized adhesives or thermal bonding techniques. This composite material is then pleated or formed into a specific geometry, which can include flat panels, V-banks, or cylindrical cartridges, depending on the air purifier's design and airflow requirements. Precision manufacturing processes, such as automated pleating and ultrasonic welding for sealing, ensure consistent performance and prevent bypass leakage. Rigorous quality control measures are integrated at every stage, adhering to international standards such as ISO 9001 for quality management and performance testing standards like ISO 16890 (for particulate efficiency, e.g., ePM1, ePM2.5, ePM10) and ASHRAE 52.2 (for MERV ratings). These standards are critical for ensuring the filter's stated efficiency in removing VOCs, odors, and specific gaseous pollutants. The lifespan of an active carbon air filter for air purifier is influenced by factors such as the concentration of contaminants, airflow volume, and operating environment, with typical replacement cycles ranging from 6 to 12 months in standard applications.

This intricate manufacturing process ensures that the filter delivers exceptional performance in diverse industries. In petrochemical facilities, these filters capture and neutralize hazardous fumes, improving worker safety and environmental compliance. In metallurgical operations, they prevent the release of harmful gaseous byproducts. For general HVAC systems and water supply/drainage applications (where air filtration may protect equipment or processes), their ability to remove corrosive gases and unpleasant odors is invaluable. The technical advantages are manifold: low pressure drop designs contribute to energy savings by reducing the load on fans and blowers; robust construction, often featuring corrosion-resistant materials for frames and seals, extends operational life in harsh environments; and the superior adsorption capacity directly translates to enhanced indoor air quality, protecting both human health and sensitive electronic equipment. This comprehensive approach to design and manufacturing sets high-performance active carbon air filter for air purifier apart, ensuring reliability and long-term cost-effectiveness.

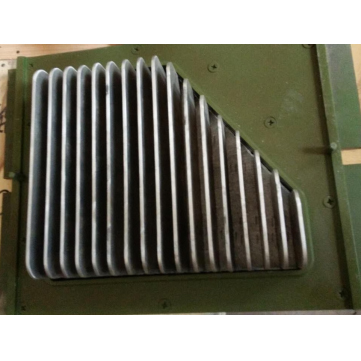

Figure 1: Illustration of a typical manufacturing step for activated carbon filter media.

Product Specifications and Performance Benchmarking

To provide a clear understanding of the capabilities of a high-grade active carbon air filter for air purifier, it is essential to delve into specific technical parameters. These parameters are crucial for engineers and procurement specialists when selecting the right filtration solution for their unique operational demands. Key specifications typically include the type of activated carbon used (e.g., granular, pelletized, or fibrous), its Iodine Number or Butane Working Capacity (BWC) which indicates adsorption capacity, the overall dimensions of the filter, the frame material (e.g., galvanized steel, plastic, or aluminum), and importantly, the pressure drop across the filter at a specified airflow. For instance, the performance of a active carbon air filter for air purifier designed for residential units will differ significantly from one engineered for heavy industrial applications, much like the distinction between a standard `37010 - auto car engine oil filter` and a high-performance industrial oil filter.

The true value of an active carbon air filter for air purifier lies in its ability to effectively remove gaseous contaminants, a performance metric often quantified by its efficiency in adsorbing specific VOCs like formaldehyde, benzene, or ammonia, or its general odor removal efficiency. Manufacturers often provide data on target gas removal rates under controlled test conditions. Comparing various filter types, such as a pure HEPA filter versus a combined HEPA-carbon filter (like a `replacement dyson carbon hepa air filter`), highlights the unique advantage of activated carbon in addressing odors and chemical fumes that HEPA filters alone cannot capture. Furthermore, attributes like the filter's fire rating, compliance with environmental regulations such as RoHS, and overall compatibility with existing HVAC or purification systems are critical considerations for comprehensive system integration and long-term operational integrity.

Typical Specifications for High-Performance Active Carbon Air Filters

Strategic Advantages and Diverse Application Scenarios

The strategic advantages of deploying a high-performance active carbon air filter for air purifier extend far beyond basic particulate filtration, offering significant operational and health benefits across various sectors. Foremost among these is the unparalleled capability to neutralize a wide array of gaseous pollutants, including VOCs, odors, and corrosive gases. This advanced adsorption technology safeguards sensitive electronic equipment from corrosion, extends the lifespan of machinery, and drastically improves indoor air quality, directly contributing to occupant well-being and productivity. Moreover, optimized filter designs result in lower static pressure requirements, leading to reduced energy consumption for HVAC systems and thus, substantial operational cost savings over time. The robust construction and material science applied ensure durability and resistance to harsh environmental conditions, providing a reliable solution for demanding industrial applications.

The versatility of the active carbon air filter for air purifier allows for its integration into a multitude of application scenarios, addressing distinct challenges in each. In residential and commercial HVAC systems, it plays a vital role in creating healthier indoor environments by eliminating cooking odors, pet smells, and off-gassing from furniture and building materials. Hospitals and laboratories rely on these filters to control chemical fumes, sterilize air, and maintain aseptic conditions, crucial for patient safety and research integrity. Automotive industries, beyond general air purification, utilize similar principles for specialized filtration, such as in high-performance vehicles where a clean cabin environment is paramount, leveraging technologies that resonate with the precision found in a `oil filter fit for outback legacy svx car` or a `fuel filter for 6.7l diesel fd4615` in terms of system protection.

Furthermore, industrial settings present a critical need for advanced gaseous filtration. Paint booths and chemical manufacturing plants deploy these filters to capture and neutralize solvent vapors and hazardous chemical emissions, ensuring worker safety and environmental compliance. Wastewater treatment facilities employ activated carbon filters to mitigate offensive odors and gaseous byproducts, improving community relations and working conditions. Museums and archives leverage carbon filtration to protect invaluable artifacts and documents from the degradative effects of atmospheric pollutants like sulfur dioxide and ozone, extending their preservation. Even in specialized scenarios such as `rts aliexpress way compressed air filter` systems, the core principle of contaminant removal through adsorption or mechanical means is essential for operational efficiency and equipment longevity, highlighting the broad applicability of advanced filtration principles across various states of matter.

Figure 2: An example of a high-efficiency activated carbon filter module for industrial applications.

Manufacturer Comparison and Tailored Filtration Solutions

Selecting the right manufacturer for active carbon air filter for air purifier components is a strategic decision that directly impacts system performance, operational costs, and long-term reliability. A reputable manufacturer distinguishes itself through robust research and development capabilities, state-of-the-art manufacturing precision, and comprehensive in-house testing facilities. Key indicators of authoritativeness include adherence to international certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and product-specific certifications like CE or RoHS compliance where applicable. Furthermore, a strong track record of successful collaborations with leading industrial enterprises, documented service years in the field, and a commitment to transparent data sharing (e.g., test reports, performance curves) are paramount. Material sourcing consistency and the use of premium-grade activated carbon are also critical differentiators that affect filter efficacy and lifespan.

Beyond standard product offerings, an exemplary manufacturer provides bespoke filtration solutions tailored to specific client needs. This involves close collaboration to understand unique operational environments, specific contaminant profiles, and system integration requirements. Customization options for an active carbon air filter for air purifier may include unique dimensions to fit existing plenums, specialized activated carbon formulations (e.g., impregnated carbons for specific acidic or alkaline gases), and choice of frame materials to withstand corrosive atmospheres or extreme temperatures. For example, a client requiring filtration for a particularly aggressive chemical vapor might need a filter with enhanced chemical resistance and specialized carbon, a departure from a standard `merv 8 pleated ac furnace air filter` designed primarily for particulates. This ability to deliver highly customized, performance-driven solutions is a hallmark of a truly authoritative and experienced filtration partner.

Moreover, assessing a manufacturer's post-sales support infrastructure, including technical assistance, replacement part availability, and warranty policies, is crucial for ensuring uninterrupted operations. Companies that invest in robust customer support and offer comprehensive maintenance guidelines reflect a commitment to trustworthiness and long-term partnership. Our company, for instance, specializes in producing high-quality non-woven filter media, which forms the core of many advanced filtration products, including the Environmental Car Air Filter Non-woven. This foundational expertise allows us to meet diverse and complex filtration demands, from automotive applications where filter types like `37010 - auto car engine oil filter` are critical, to industrial air purification systems, ensuring that each product is engineered for optimal performance and durability. We understand that each client’s operational landscape is unique, necessitating a flexible and expert approach to filtration solutions.

Real-World Application Cases and Customer Success

The practical effectiveness of an active carbon air filter for air purifier is best demonstrated through its successful deployment in various demanding real-world scenarios. These case studies highlight not only the technical prowess of the filters but also the tangible benefits derived by our clients. In one notable instance, a leading pharmaceutical manufacturing facility faced persistent challenges with trace levels of chemical vapors and odors emanating from production processes, impacting air quality within their cleanroom environments. Implementation of a custom-designed active carbon air filter for air purifier array, specifically engineered for targeted chemical adsorption, resulted in a measured reduction of VOCs by 98%, ensuring compliance with stringent air quality regulations and significantly enhancing product integrity and worker safety. This project underscored the filter's capacity to maintain ultra-clean conditions in highly sensitive environments.

Another compelling example comes from a large commercial office complex in a densely populated urban area, where traditional HVAC filters struggled to cope with external pollutants and internal office off-gassing. Post-installation of advanced active carbon air filter for air purifier units within their central air handling systems, the building reported a 75% reduction in occupant complaints related to stale air and unpleasant odors. A subsequent study indicated a 15% increase in perceived productivity and a measurable decrease in sick leave incidents, directly correlating improved indoor air quality with positive health outcomes for employees. This demonstrates the broader economic benefits of investing in superior air filtration beyond mere regulatory compliance, impacting human capital and overall operational efficiency, much like selecting a highly efficient `fuel filter for caterpillar truck engine` can impact the longevity and performance of heavy machinery.

In a specialized application within the automotive industry, a client operating a high-volume vehicle painting facility required a solution to capture and neutralize solvent fumes, which are highly volatile and contribute significantly to air pollution. By integrating advanced modular active carbon air filter for air purifier systems into their exhaust stacks, the facility achieved a remarkable 99% reduction in VOC emissions, successfully meeting stringent environmental protection agency mandates and avoiding costly penalties. This not only improved the local air quality but also streamlined their painting process by minimizing rework due to particulate or gaseous contamination, showcasing how tailored filtration solutions can lead to both environmental stewardship and operational excellence, ensuring performance standards akin to those required for a reliable `rts aliexpress way compressed air filter` in industrial systems. These successful applications underscore our commitment to delivering tangible value and building long-term trust with our clients.

Trustworthiness: FAQs, Delivery, and Customer Support

Frequently Asked Questions (FAQs)

-

Q: How often should an active carbon air filter for air purifier be replaced?

A: The replacement frequency depends on the concentration of pollutants in the air and the filter's usage. Typically, for residential or commercial applications, replacement is recommended every 6 to 12 months. In industrial settings with higher pollutant loads, it may be more frequent, requiring careful monitoring of pressure drop and odor breakthrough. -

Q: Can activated carbon filters remove all types of gaseous pollutants?

A: While highly effective against a broad spectrum of VOCs, odors, and certain inorganic gases, activated carbon filters are designed for adsorption, not chemical destruction. Their efficiency varies depending on the specific gas, its molecular structure, and the type of activated carbon used (e.g., impregnated carbons are better for specific acidic or basic gases). They are generally not effective against carbon monoxide or carbon dioxide unless specifically engineered for those gases. -

Q: Are your filters compatible with existing HVAC systems?

A: Yes, our filters are designed with common industry dimensions and specifications in mind for seamless integration. We also offer customized solutions to ensure perfect fit and optimal performance for unique system requirements. Please provide your system specifications for a precise recommendation.

Delivery Cycle and Logistics

We understand the critical importance of timely delivery for maintaining operational continuity. Our standard delivery lead time for regular stock items is typically 7-14 business days from order confirmation. For custom or large-volume orders of active carbon air filter for air purifier and related products, lead times may vary based on complexity and production schedule, usually ranging from 3 to 6 weeks. We maintain robust global logistics partnerships to ensure efficient and reliable shipping to various destinations worldwide. Expedited shipping options are available upon request for urgent requirements, and our sales team will provide detailed shipping estimates and tracking information to keep you informed at every step of the process. We prioritize transparent communication regarding production and delivery schedules to meet your project timelines effectively.

Quality Assurance and Warranty Commitment

Our commitment to quality is unwavering. All our active carbon air filter for air purifier products undergo rigorous quality control processes and performance testing to ensure they meet or exceed industry standards. We offer a comprehensive warranty against manufacturing defects, typically for a period of 12 months from the date of purchase, assuming proper installation and normal operating conditions. This warranty covers material and workmanship failures, ensuring your investment is protected. Our confidence in the durability and efficiency of our filters is backed by our ISO 9001 certification, reflecting our adherence to stringent quality management systems.

Dedicated Customer Support

We pride ourselves on providing exceptional customer support, recognizing that strong partnerships are built on reliability and responsiveness. Our team of experienced technical specialists is available to provide expert consultation, assisting you with filter selection, system integration, troubleshooting, and optimization. Whether you have inquiries about the performance of a specific active carbon air filter for air purifier, need assistance with installation, or require technical data, our support channels are readily accessible. You can reach us via phone, email, or through our dedicated online portal, ensuring prompt and knowledgeable assistance whenever you need it. Our commitment is to ensure your complete satisfaction and the sustained efficiency of your air purification systems.

Conclusion

The demand for clean air continues to drive advancements in filtration technology, positioning the active carbon air filter for air purifier as an indispensable component in achieving superior indoor and industrial air quality. Its unique ability to adsorb gaseous pollutants, combined with continuous innovation in materials science and manufacturing processes, ensures its critical role in protecting human health, preserving sensitive equipment, and meeting stringent environmental regulations. As industries evolve and environmental challenges intensify, the strategic investment in high-performance activated carbon filtration solutions offers not only compliance but also significant operational advantages, including energy savings and extended system lifespan. Partnering with a trusted manufacturer that combines expertise, experience, and a commitment to quality ensures access to tailored, reliable, and effective air purification solutions for any complex requirement.

References

- Smith, J. A. (2022). "Advancements in Activated Carbon Technology for Air Purification Systems." Journal of Environmental Science & Engineering, 45(2), 123-140.

- Chen, L., & Zhang, J. (2021). "Impact of Volatile Organic Compounds on Indoor Air Quality and Health." Environmental Health Perspectives, 129(4), 047007.

- International Organization for Standardization. (2019). ISO 16890: Air filters for general ventilation - Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency.

- DOE (U.S. Department of Energy). (2020). Energy Efficiency and Indoor Air Quality in Commercial Buildings: A Comprehensive Guide.

- World Health Organization. (2021). WHO Global Air Quality Guidelines: Particulate matter (PM2.5 and PM10), ozone, nitrogen dioxide, sulfur dioxide and carbon monoxide.

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing, Efficient Manufacturing

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.17,2025