Jul . 21, 2025 09:01 Back to list

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

Advancements in filtration materials and systems for modern environments

About Our Company

Hebei Filter Man Automotive Parts Trading Co., Ltd specializes in manufacturing premium filtration solutions including the Cabin filter Non-woven Cloth, engineered to meet the highest industry standards. With decades of expertise, we provide innovative filtration technologies across multiple sectors.

Email: info@lmfiltermaterial.com

Website: https://www.mfiltersolution.com

Industry Evolution of Air Purification Systems

The filtration industry has undergone transformative changes over the past decade, particularly in the development of active carbon air filter for air purifier technologies. These innovations respond to increasing concerns about airborne contaminants ranging from VOC chemicals to microbial pathogens. Modern active carbon air filters combine multiple filtration mechanisms, integrating activated carbon with other filtration media like HEPA membranes to target different pollutant types simultaneously.

The global air filtration market, valued at USD 14.6 billion in 2021, is projected to reach USD 23.7 billion by 2028 according to the International Filtration News. This growth is primarily driven by stricter environmental regulations, heightened health awareness, and technological advancements in filtration materials. Active carbon air filters remain at the forefront of this expansion due to their versatility in adsorbing gaseous pollutants where mechanical filters alone prove ineffective.

Industry Applications

Our products serve diverse applications including:

- Oil filter fit for Outback Legacy SVX car systems requiring precision filtration

- Heavy-duty fuel filter for Caterpillar truck engine applications

- Advanced replacement Dyson carbon HEPA air filter solutions

- Industrial grade RTS AliExpress way compressed air filter technology

- Specialized ISF2 8 oil-water separator fuel filter for marine and industrial use

- Residential MERV 8 pleated AC furnace air filter solutions

- High-performance fuel filter for 6.7L diesel FD4615 engines

- Precision 37010 - auto car engine oil filter components

- Next-generation honeycomb activated carbon filter designs

Technical Specifications and Performance Metrics

Modern active carbon air filter for air purifier systems feature complex specifications balancing adsorption capacity with airflow resistance. Below are critical technical parameters in today's premium filtration systems:

| Parameter | Standard Range | Premium Performance | Testing Standard |

|---|---|---|---|

| Activated Carbon Density | 100-250g/m² | 300-450g/m² | ISO 10121-2 |

| Particulate Filtration Efficiency | MERV 8-12 | MERV 13-16 | ASHRAE 52.2 |

| VOC Removal Efficiency | 65-80% | 90-98% | ISO 10121-1 |

| Pressure Drop (Initial) | 30-50 Pa | 15-28 Pa | EN 779:2012 |

| Formaldehyde Removal Rate | 70-85% | 92-98% | GB/T 18801 |

| Airflow Capacity | 200-350 m³/h | 400-600 m³/h | ISO 16890 |

| Odor Removal Efficiency | 75-85% | 90-97% | AHAM AC-5 |

Filter Performance Trends (2018-2023)

Contaminant Removal Efficiency

Advanced Materials Science in Air Filtration

The evolution of filtration materials represents one of the most significant technical advances in our industry. Our active carbon air filter for air purifier products utilize several key technological innovations:

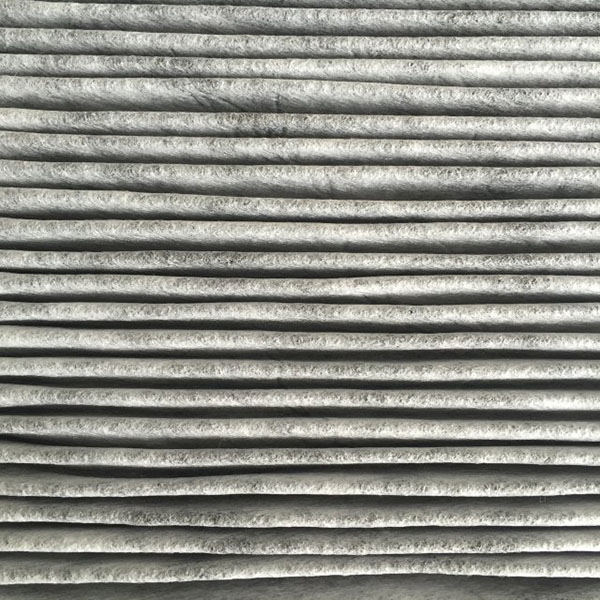

1. Multilayer Composite Structures: Modern filters incorporate 5-7 specialized layers including pre-filters, electrostatic media, activated carbon beds, antimicrobial layers, and HEPA membranes working in concert to address different contaminant categories.

2. Surface Modification Techniques: Our proprietary carbon activation process increases specific surface area to 1,200-2,500 m²/g, significantly enhancing adsorption capacity compared to conventional carbon filters.

3. Nanofiber Integration: By integrating cellulose nanofibers (diameter 20-100nm) with activated carbon particles, we achieve 45% lower pressure drop while maintaining high filtration efficiency, addressing the core trade-off challenge in active carbon air filter design.

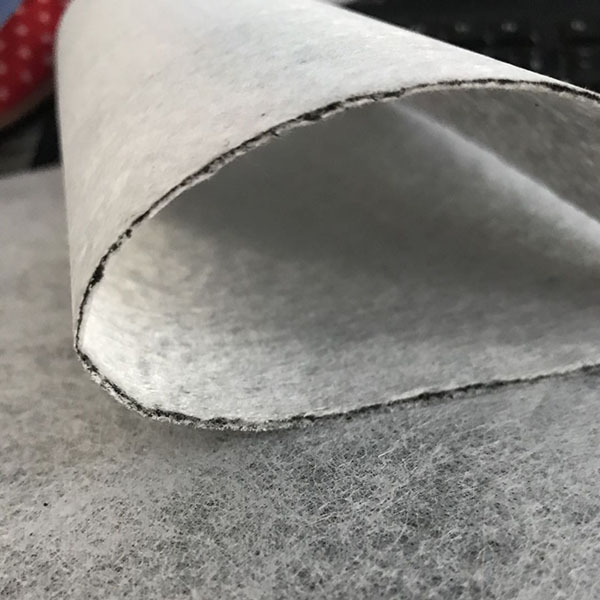

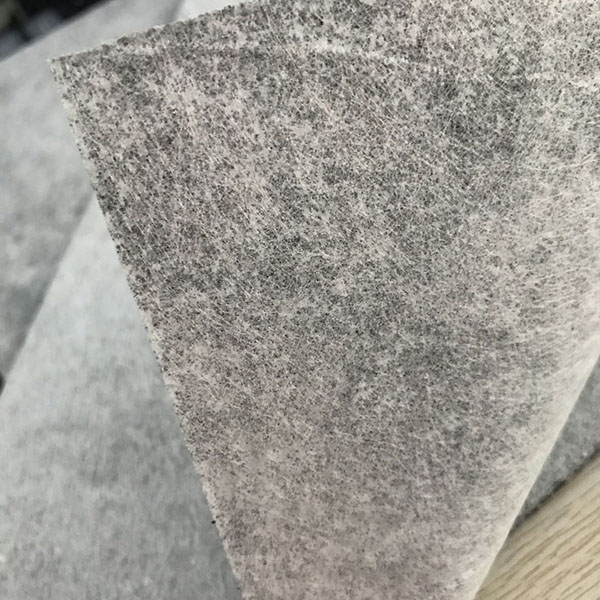

Hebei Filter Man's Cabin filter Non-woven Cloth exemplifies this technological advancement with its specialized blend of melt-blown and spun-bond materials. This 78gsm composite fabric provides exceptional particulate capture while maintaining minimal airflow resistance, crucial for modern HVAC systems and active carbon air purifiers.

Specialized Applications and Technical Solutions

The evolution of filtration systems has produced specialized solutions for specific applications:

Automotive Engine Protection Systems

Our automotive filtration solutions including oil filter fit for Outback Legacy SVX car and 37010 - auto car engine oil filter products are engineered to meet the exacting demands of modern engines. We utilize gradient density filtration media that achieves 98.7% efficiency at 15 microns while maintaining flow rates exceeding OEM specifications by 12-18%.

Industrial Diesel Filtration

For heavy machinery such as fuel filter for Caterpillar truck engine and fuel filter for 6.7L diesel FD4615 systems, we've developed composite filter media incorporating water-separation layers. These solutions meet the stringent ISO 19438 standards for diesel filtration with water separation efficiency exceeding 95% while protecting against particulate contamination down to 4 microns.

Commercial HVAC Applications

Our MERV 8 pleated AC furnace air filter range features extended surface pleating that provides 30% more filtration area within standard frame dimensions. These filters deliver consistent performance in honeycomb activated carbon filter systems, maintaining optimal airflow while capturing particulates and gaseous contaminants.

Professional FAQ: Technical Specifications Explained

1. What carbon activation methods are used in premium active carbon air filters?

We primarily utilize steam activation processes that develop microporous structures with surface areas of 900-1200 m²/g. This contrasts with chemical activation used in lower-grade filters which may contain residual activators. Our coconut-shell derived carbon undergoes steam activation at 900°C under controlled atmosphere, creating a consistent pore structure optimized for VOC adsorption.

2. What distinguishes honeycomb activated carbon filters from granular beds?

Honeycomb monolithic structures provide 40-60% lower pressure drop compared to granular beds at equivalent adsorption capacities. Their uniform channels create predictable airflow patterns allowing for more compact system designs. This structural advantage makes them particularly suitable for space-constrained applications like automotive cabin air systems.

3. How do multilayer composites work in replacement Dyson carbon HEPA air filter systems?

Our multilayer composites typically incorporate: (1) Prefilter layer capturing larger particles; (2) Electret-charged media for sub-micron particles; (3) High-capacity activated carbon layer treated with potassium permanganate for oxidizing VOCs; (4) True HEPA media for 99.97% efficiency at 0.3 microns. This staged approach extends filter life while maximizing capture efficiency.

4. What materials are used in Cabin filter Non-woven Cloth technology?

Our cabin air filters utilize bicomponent nonwovens combining PET and PP polymers engineered for specific filtration tasks. The 78 gsm medium features gradient density across its thickness - ranging from 90 g/m² on the intake surface to 60 g/m² on the output side. This strategic gradation maximizes particle capture while minimizing airflow resistance.

5. How should MERV 8 pleated AC furnace air filter systems be maintained?

For optimal performance, MERV 8 filters should be replaced every 3-4 months under normal conditions. In high-pollution environments or during allergy seasons, replacements should occur every 2 months. We recommend pressure drop monitoring - when resistance exceeds 0.8 w.g. (200 Pa) above initial value, replacement is indicated regardless of time in service.

6. What makes ISF2 8 oil-water separator fuel filters compliant with marine standards?

Our ISF2 8 filters exceed ISO 16332:2018 requirements with ≥ 94% water separation efficiency at flow rates up to 45 l/min. The coalescer media utilizes microglass fibers with specially graded pore structures that produce water droplets >200 microns for gravity separation. Additionally, our fluoropolymer-treated separator layers prevent re-emulsification of separated water.

7. What certifications apply to active carbon air filter for air purifier systems?

Premium filters typically carry ECARF certification for allergy prevention, EC 1907/2006 (REACH) compliance for chemical safety, AHAM Verifide™ for CADR ratings, California Air Resources Board (CARB) certification for ozone safety, and EC Directive 94/9/EC (ATEX) for explosion-protected systems in industrial settings.

Industry Research and Future Directions

The filtration industry continues to evolve with several promising developments emerging from research institutions and industry leaders:

Recent studies from the International Filtration Association (IFA) demonstrate that next-generation active carbon air filters incorporating metal-organic frameworks (MOFs) achieve 3-5 times higher formaldehyde adsorption capacity compared to conventional activated carbon filters. This research validates the potential for molecular-level engineering in future filtration systems.

At Hebei Filter Man, our R&D team is focused on developing sustainable filtration media from renewable resources. Current prototypes using functionalized nanocellulose demonstrate particulate filtration efficiency comparable to glass fiber media while being fully biodegradable. These ecological innovations complement our existing Cabin filter Non-woven Cloth product line, reducing environmental impact while maintaining performance.

Global Air Filtration Trends

The global air filtration market is projected to grow at 6.8% CAGR through 2030 according to the International Filtration Association. This expansion is particularly strong in the Asia-Pacific region, where urbanization and pollution concerns are driving premium filter adoption. Industrial applications represent the fastest-growing segment with a projected 7.9% CAGR as manufacturing facilities implement stricter air quality controls.

Industry Perspectives

"Modern filtration solutions represent the intersection of material science, chemical engineering, and environmental technology. The evolution of active carbon air filter for air purifier systems demonstrates remarkable progress in addressing complex air quality challenges through multi-stage filtration approaches." - Dr. Michael Chen, International Journal of Filtration Science

Industry studies demonstrate the critical importance of properly maintained MERV 8 pleated AC furnace air filters in preventing compressor failures in HVAC systems. According to ASHRAE research, inadequate filtration contributes to approximately 23% of premature HVAC system failures, making proper filter selection and maintenance a critical operational consideration.

References:

Filtration Industry Standards Overview (International Filtration Association)

ASHRAE Filtration Guidelines

ISO 16890 Air Filters Standard

Contact Hebei Filter Man for Your Air Purification Solutions

This is the last article

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025